A History of Quality & On-Time Delivery

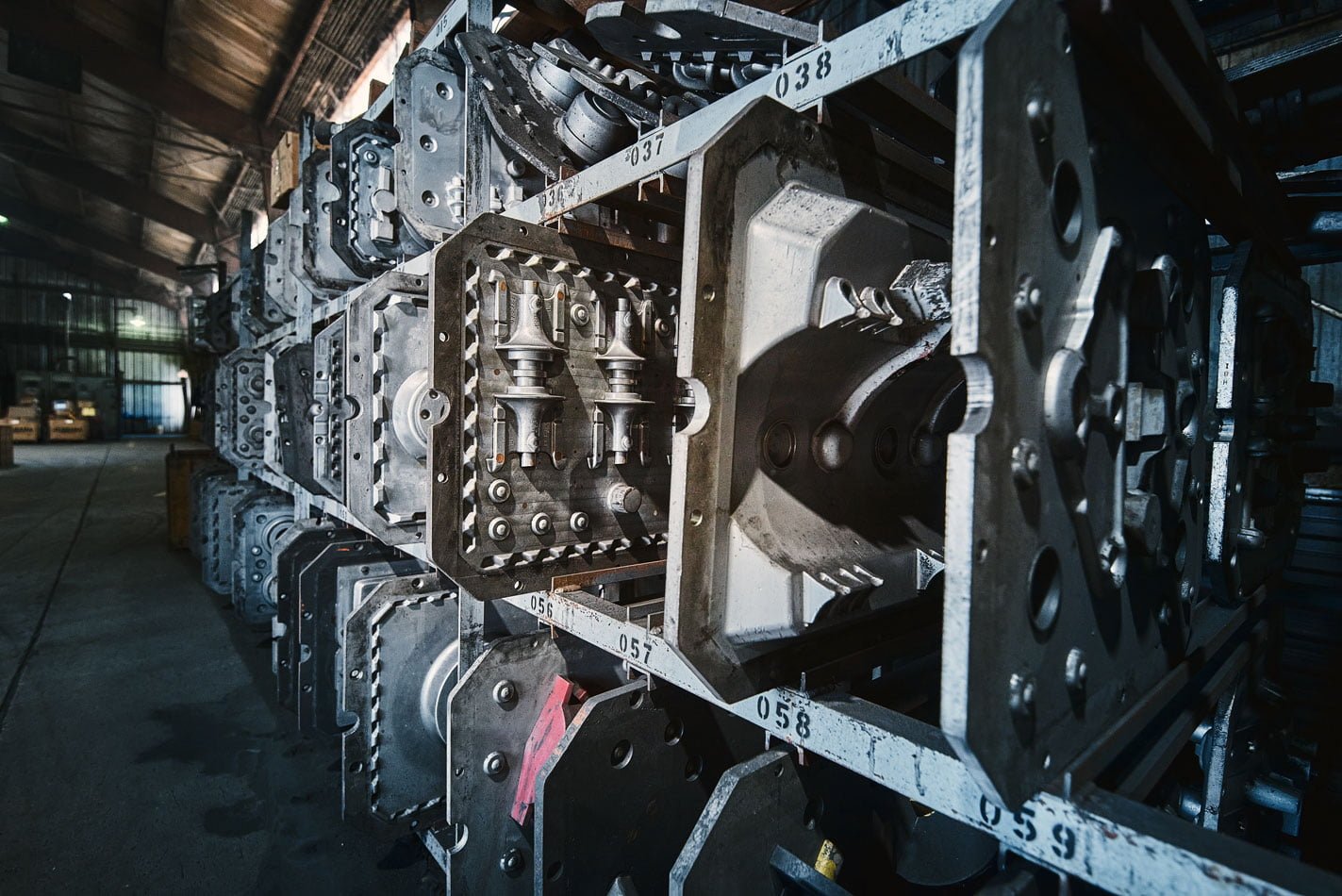

A Reputation FORGED on Quality.

With more than 45 years of experience, Franklin Iron is dedicated to producing quality casting for competitive prices.

Capabilities

Our capabilities extend from custom pattern design to in-house heat treatment to specialty packaging to provide customers with a full-service, start-to-finish casting process.

- Ductile Iron

- Patterns

- Custom Cores

- Speciality Packaging

- Grinding

- Shot Blasting

- Machining & Assembly

Speciality Services

We take pride in offering a diverse range of specialty services with a dedication to customization ensuring customer’s unique needs are not just met but exceeded.

- Specialty Coatings & Paint

- Heat Treating

- Specialty & Custom Iron Formulations

- Custom Kiting

- Inventory Management

- Chemical & Physical Component Certification

Our Services

We offer the quality products and services you can depend on and the small-town, down-to-earth team that you can trust to offer you the best customer service out there.

Custom Pattern Design & Manufacturing

Pattern Design Optimization

Custom Core Design & Manufacturing

Ductile Iron Casting

In House Heat Treatment

Automated & Manual Grinding

Machining

Specialty Packaging

Delivery Footprint

Multi-Location / Multi-Equipment Redundancy

RELATIONSHIPS BUILT As STRONG AS IRON.

The Leading Foundry in Ductile Casting

Water & Wastewater Infrastructure

Water and wastewater infrastructure require multiple connection points where castings come into play.

Power Generation,

Transmission &

Distribution Systems

Power generation, transmission and distribution systems move electricity from one point to another through power lines that use multiple types of casting.

Vertical Transportation

Vertical transportation includes escalators, moving walkways, passenger elevators, service lifts and more. These systems require casting components to help lift and move.

Agricultural Equipment

Agricultural equipment is anything from tractors to attachments.

Heavy Trucking

Heavy trucking includes any load with an overall weight of more than 55,000 pounds. Trucks and trailers in heavy trucking require heavy-duty iron castings for multiple components.

Pumps, Hydraulics & Mechanical Systems

Pumps, hydraulics and other mechanical systems require multiple castings to work.